DeTomaso Pantera restoration project

DeTomaso Pantera, an exotic name for a potent combination of ground-pounding American muscle and Italian style. An ‘in your face’ kind of car straight out of the seventies.

DeTomaso Pantera restoration project

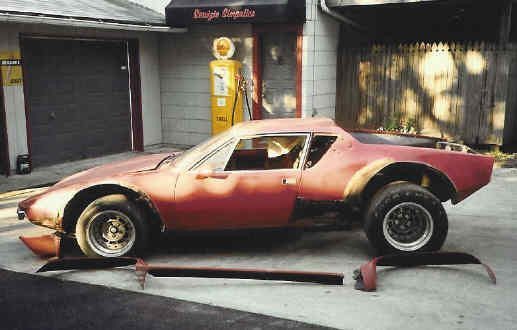

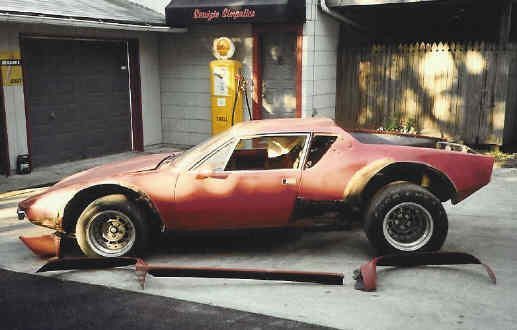

This car had been in storage a long time. And time had not been kind. But the owner, having been informed of the extent of the work required, was committed to the project.

A couple words in support of seemingly unworthy projects: Here’s the thing, exotics, along with American muscle cars and European sports cars, were designed for people who are passionate about cars. Since there are very few cars worth restoring from a strictly dollar and cents point of view, it is passion for the form that accounts for all the work being done on cars that a mere bean counter would send to the scrap yard without a second thought.

And another thing, it is easy to say that a specific car is not worth restoring given how much one could spend on some other car in better condition. That may be true, but that other car is always somebody else’s. Somebody else’s choice of quality, of time and money invested; everything right down to the color. So if I’ve held onto the car my Dad owned, and thirty years later want to restore this rust bucket, some other car just won’t do. Price doesn’t even show up on the radar, it’s a non-issue

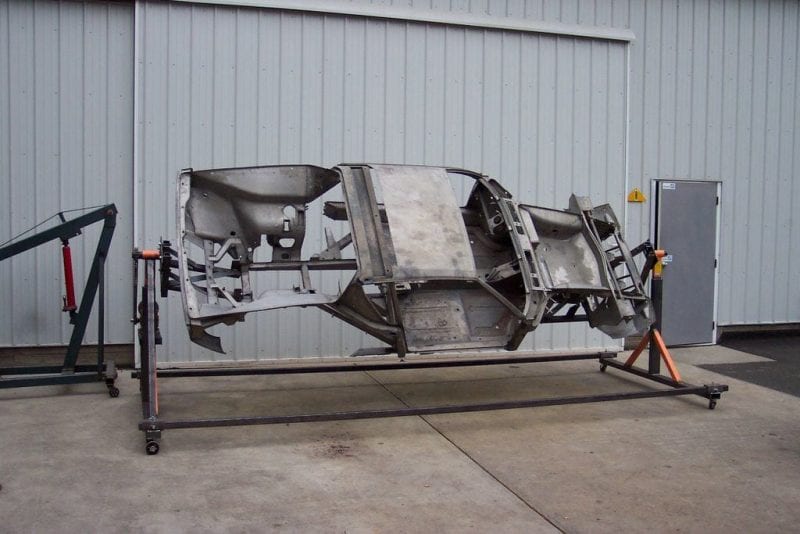

Pantera in rotisserie

So this is a total teardown, rotisserie restoration. In fact, we determined that the 351-C was salvageable and that the ZF gearbox needed minimal work, the support structure of the unibody was sound and that it was mainly the exterior sheet metal that had taken most of the abuse, along of course with the interior.

Panteras, like most of the exotics of that age, were built with absolutely zero regard to long term corrosion protection. There are simply too many instances of dead air spaces with no allowance for drainage. Combine this with a tendency to neglect to paint or otherwise protect the inside surfaces and it almost seems like a conspiracy on the part of the Italians. You know what, they went fast and looked good and that’s all that mattered.

The crew at Exoticars-USA in Frenchtown, NJ got started completely disassembling the car down to its component parts. Phil Murphy handled the task of researching the availability of parts. He was able to order all the major panels including fenders, door skins, quarters and outer rockers.

Having obtained exterior sheet metal, the task of putting it all together is in the hands of Randy Tartanian, the resident panel beater. Fabricating inner panels out of cold rolled sheet metal is sometimes difficult when there is little of the original piece to follow. “The goal is to duplicate the function of the original part” says Randy. So using a wide variety of tools including the bending brake, English wheel, shrinker/stretcher, plasma cutter and an array of hammers, the needed panels are formed and fitted into place. Welding is accomplished with the best method for the particular job. MIG, TIG, Spot and Oxy-acethelyne welding are used.

Currently the Pantera is in the process of having the sheet metal installed. The engine is partially rebuilt and the gearbox has been serviced and resealed. The choice of color is yet to be made.